Get SMS verification code

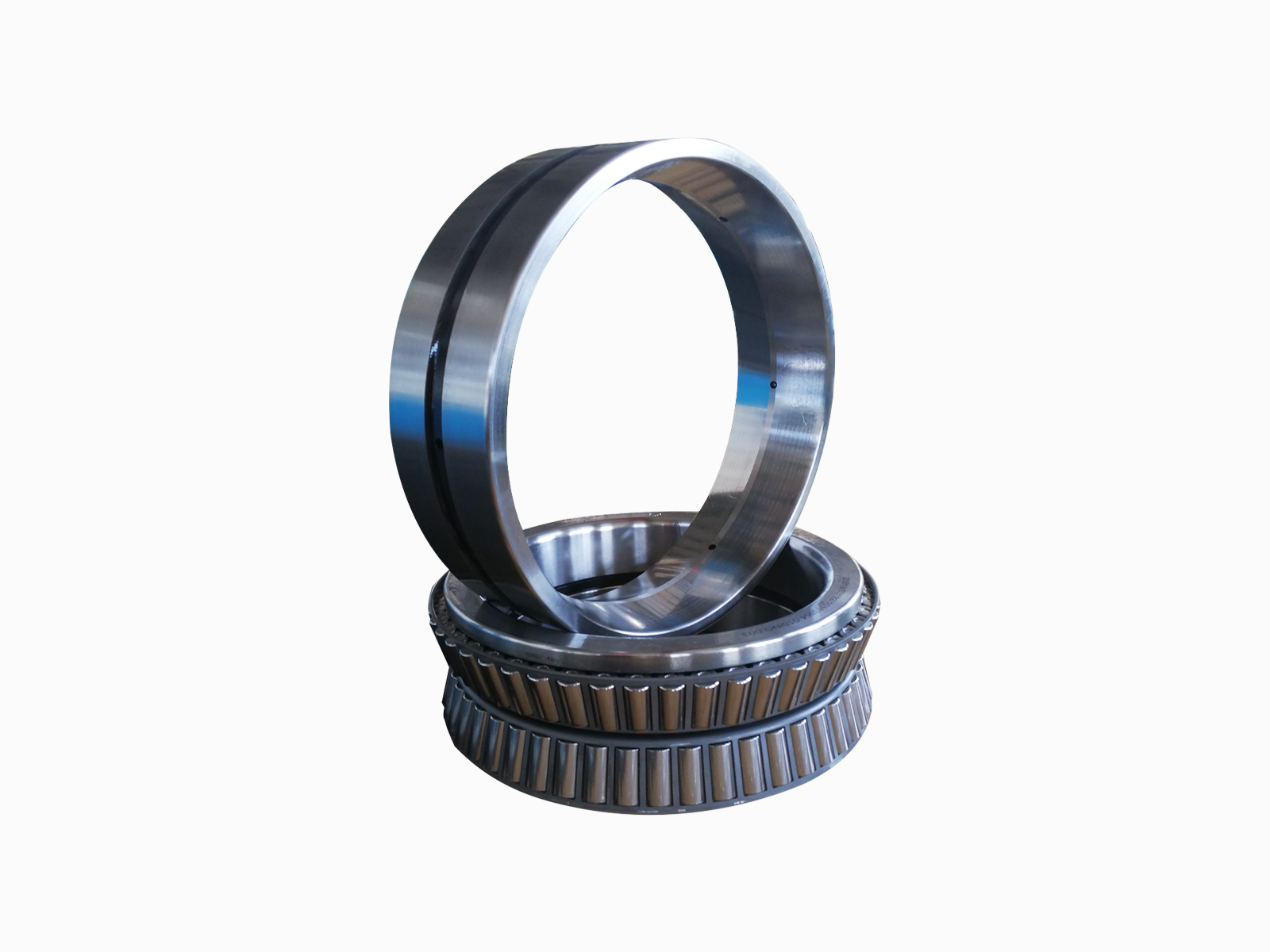

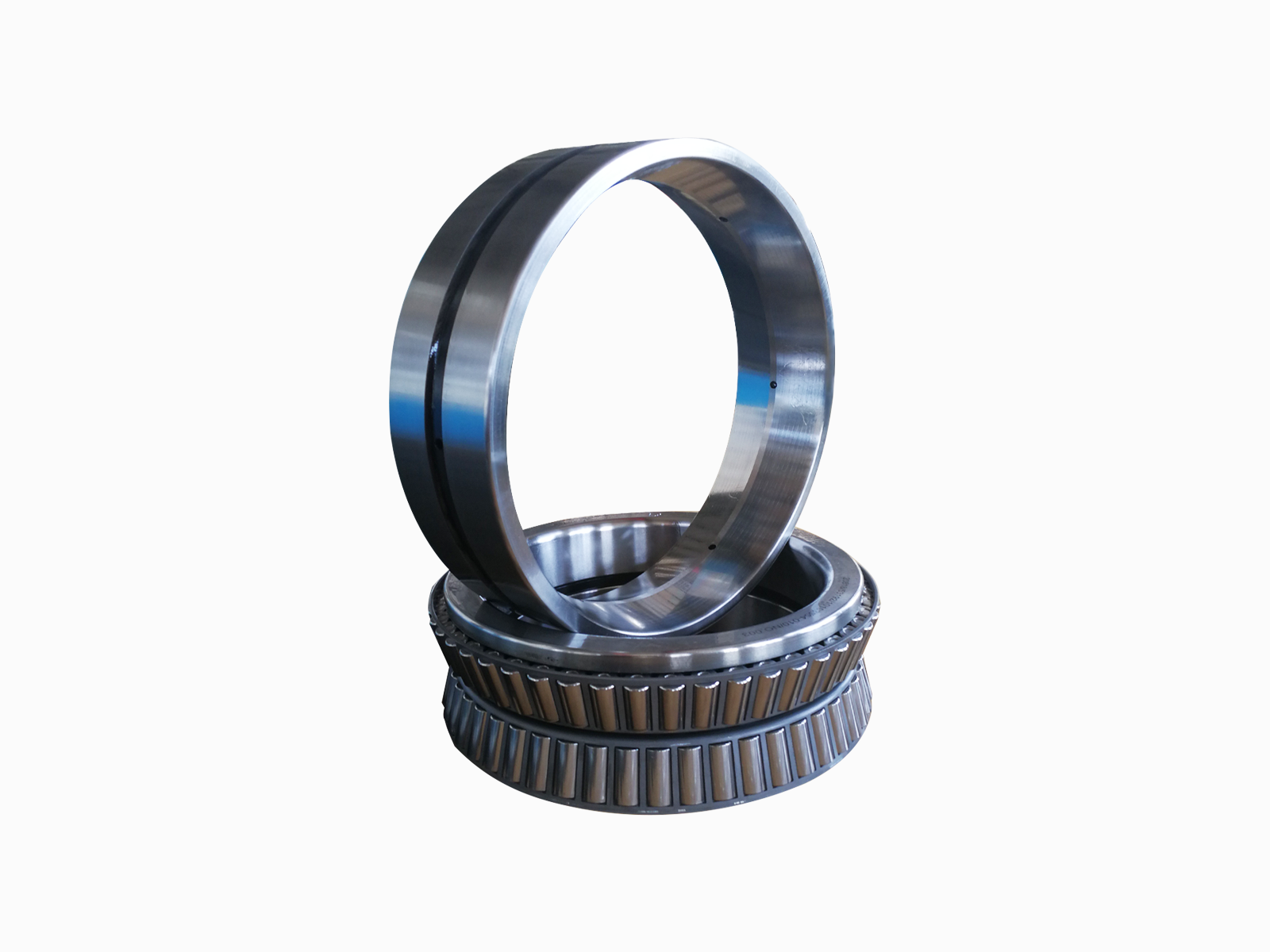

HyjgBearing tapered roller bearings are available in a wide range of designs and can also be customised to suit your specific speed, load, contamination, temperature or vibration conditions.

HyjgBearing tapered roller bearing have cup and tapered components. The cup consists of the outer ring and the tapered assembly consists of the inner ring, rollers and cage. This taper roller bearing construction can withstand combined loads and provides low friction in operation. Rigid applications of the bearings can be achieved by adjusting one single row tapered roller bearing relative to a second tapered roller bearing and applying a preload.

Hyjg Bearing tapered roller bearings are often used as a bearing solution in applications where improved performance, reduced friction or increased power density is required.

Common applications for these tapered roller bearings include

automotive wheel bearings; as well as gearboxes, axle systems and engines

Agricultural machinery shafts and general shafts

as centre frame rollers, strip straighteners or in combination with guideway elements

Helicopter transmissions

Aircraft fuel pumps

Once a taper roller bearing component starts to spall material, the bearing is considered fatigued and immediate replacement is recommended. Life expectancy can be estimated according to ISO 281. This standard estimates bearing life based on 90% reliability of all roller bearings, taking into account variables such as material, build quality, type of load, operating conditions, lubrication and contamination.

Thermal expansion of taper roller bearing components is unavoidable, but excessive heat can be mitigated by the lubricant, the construction of the raceways, cages and rollers and the overall surface area. Brief operating conditions, such as bearing start-up or a new installation, may cause temperature spikes, but this will almost always be reduced. This is the result of the thermal expansion experienced by the bearing components. Extra care should be taken when selecting bearings for precision equipment.

The temperature of Hyjg Bearing's tapered roller bearing bearings is largely determined by the operating speed. The reference speed is the speed at which the heat generated and emitted by the bearing reaches equilibrium. The limiting speed is the maximum speed at which the bearing can rotate. The limiting speed is not always as high as the reference speed, but can be exceeded if the strength of the bearing material, the friction caused by any contact seals and the lubrication used do not affect this operation.

Taper roller bearing torques can be attributed to several variables such as roller size, number of rollers, cage composition, bearing tolerances, lubricant type and fill and bearing load. Bearing torques are divided into three categories.

Start-up torque is a measure of the torque required to start one race of the bearing rotating. This is considerably higher than the running torque.

The average running torque is the average level of torque the bearing is subjected to at a consistent RPM.

Peak running torque is the maximum torque that the bearing will withstand, but is difficult to determine. This provides a measure of the consistency of a batch of bearings.

Deflection can occur between the taper roller bearing and the raceway; specifically, the end of the roller can take on a more elliptical shape. Tapered roller bearings have less deflection than many other types of bearing, so they are often used in machine tools where precise shaft positions are required. Monitoring the deflection of tapered roller thrust bearings is essential because the load distribution on the bearing shifts inwards, increasing contact stresses at certain points and causing roller and raceway wear. In many cases, preload, usually provided by springs, increases the stiffness of the bearing and improves running accuracy.

Tapered roller bearing belongs to separate bearing, and the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows of rollers installed. Single row tapered roller bearings can withstand radial load and axial load in a single direction. When the bearing bears radial load, an axial component will be generated, so another bearing that can bear the axial force in the opposite direction is needed to balance.

Tapered roller bearing belongs to separate bearing, and the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows of rollers installed. Single row tapered roller bearings can withstand radial load and axial load in a single direction. When the bearing bears radial load, an axial component will be generated, so another bearing that can bear the axial force in the opposite direction is needed to balance.

Tapered roller bearing belongs to separate bearing, and the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows of rollers installed. Single row tapered roller bearings can withstand radial load and axial load in a single direction. When the bearing bears radial load, an axial component will be generated, so another bearing that can bear the axial force in the opposite direction is needed to balance.

Copyright:Dalian Ounuo Bearing Co., Ltd

Sitemap

zhangxiao01@hotmail.com

+19093438885